Key CNC Machining Capabilities

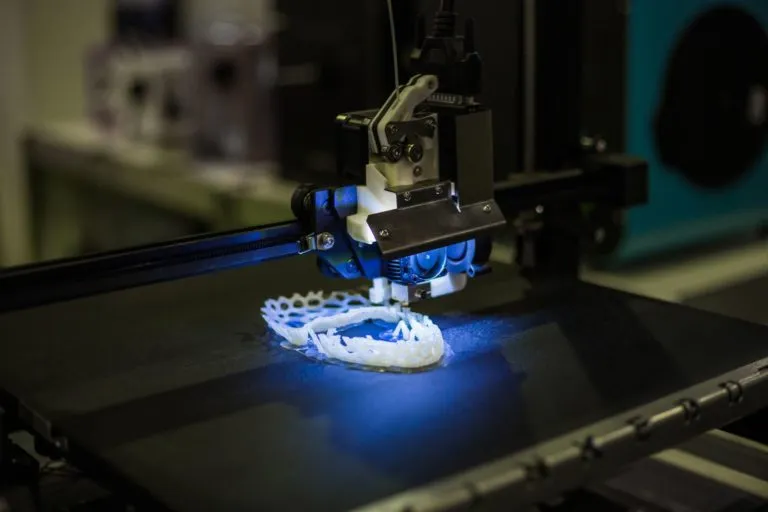

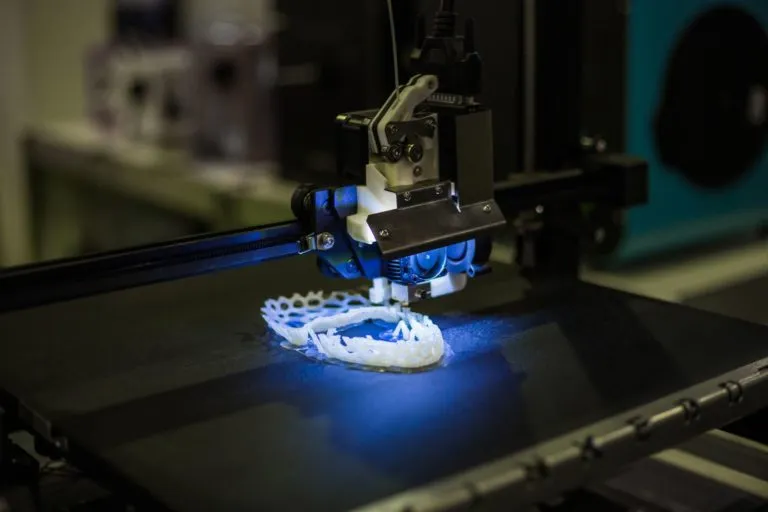

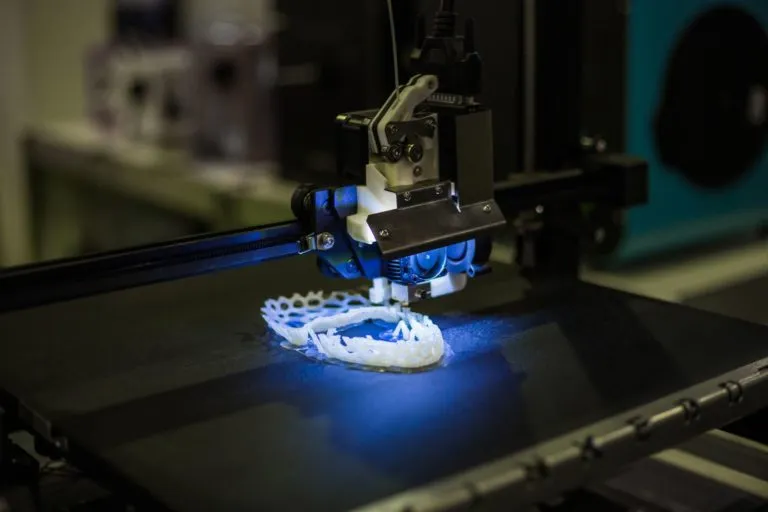

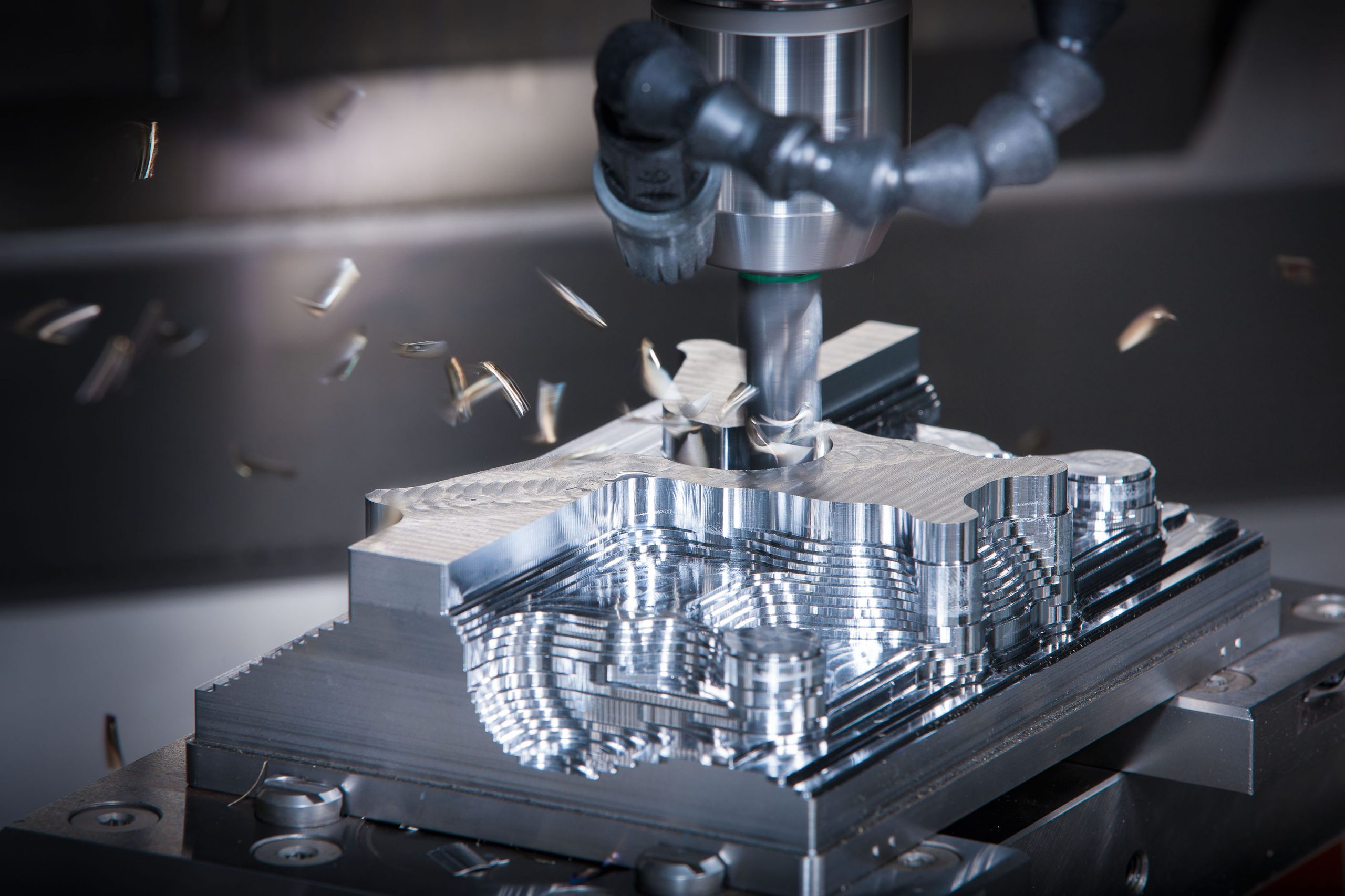

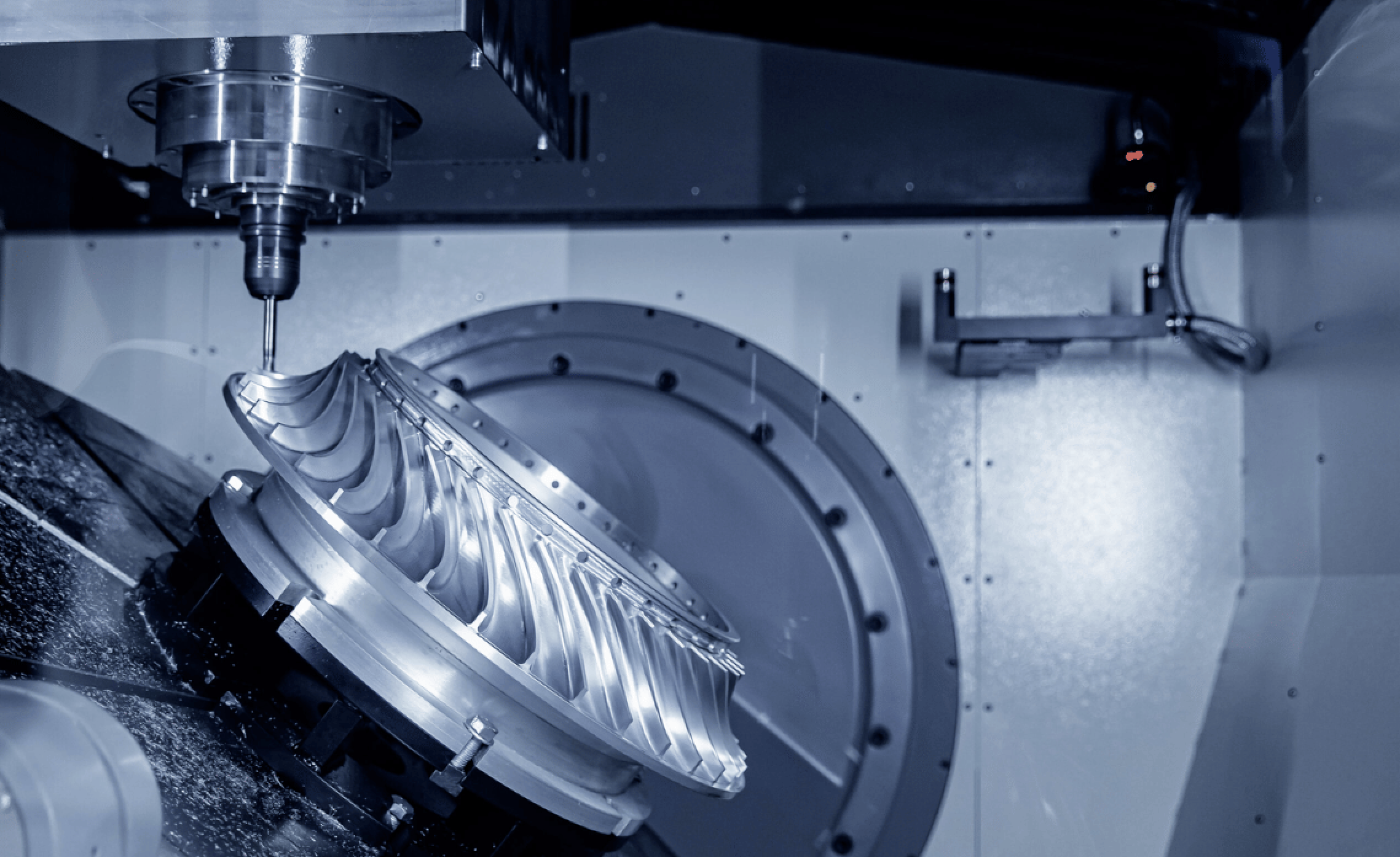

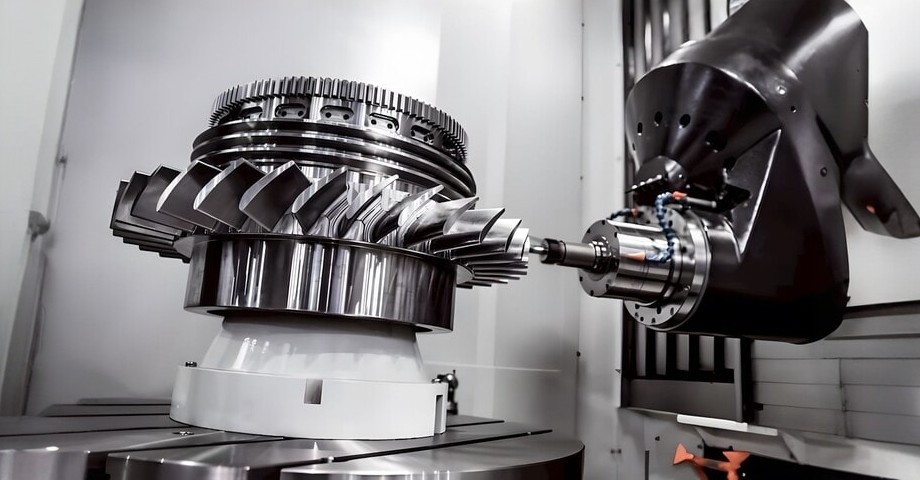

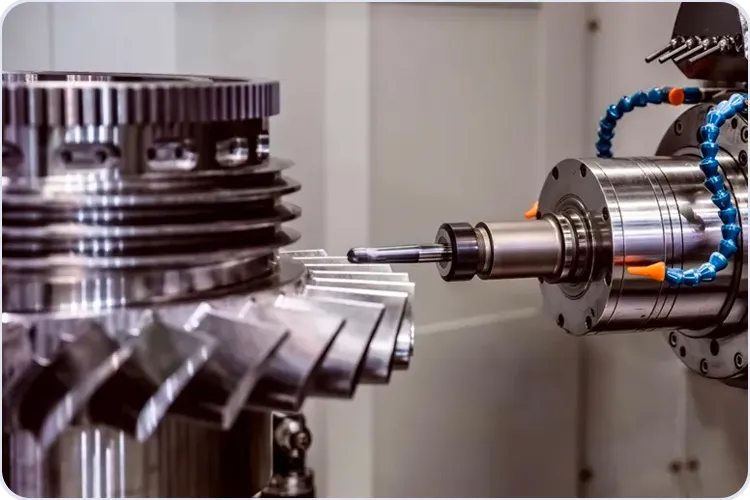

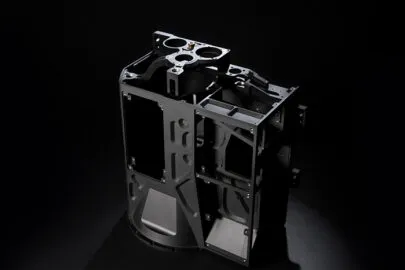

3-axis, 4-axis, and 5-axis CNC Machining

Equipped with advanced multi-axis machining centers, we specialize in producing highly complex geometries with micron-level tolerances. Our capabilities ensure precision in high-complexity components, tailored to the stringent requirements of industries such as aerospace, robotics, and medical.

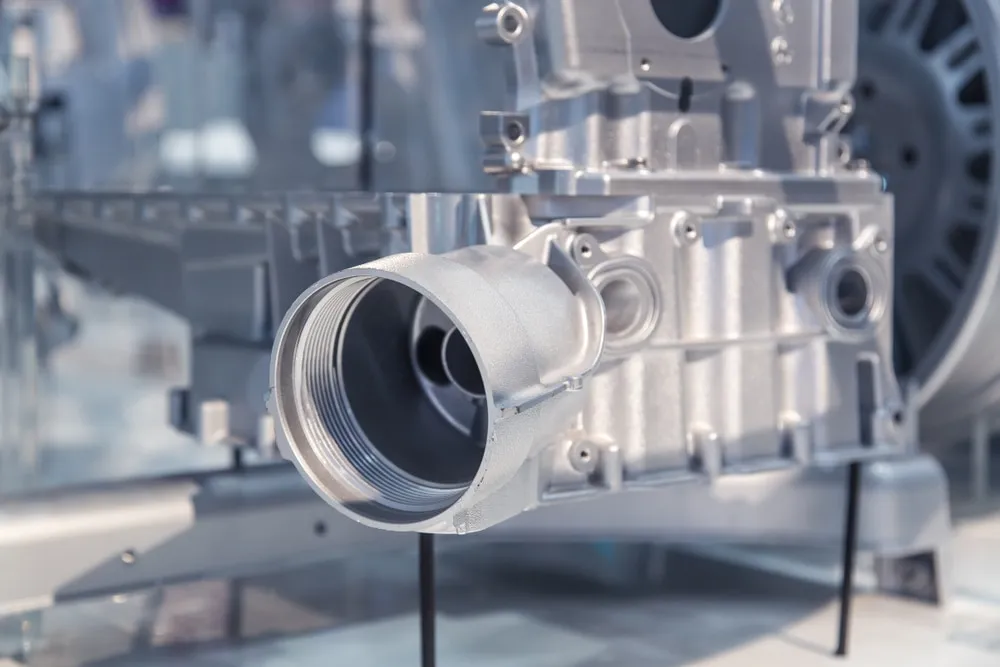

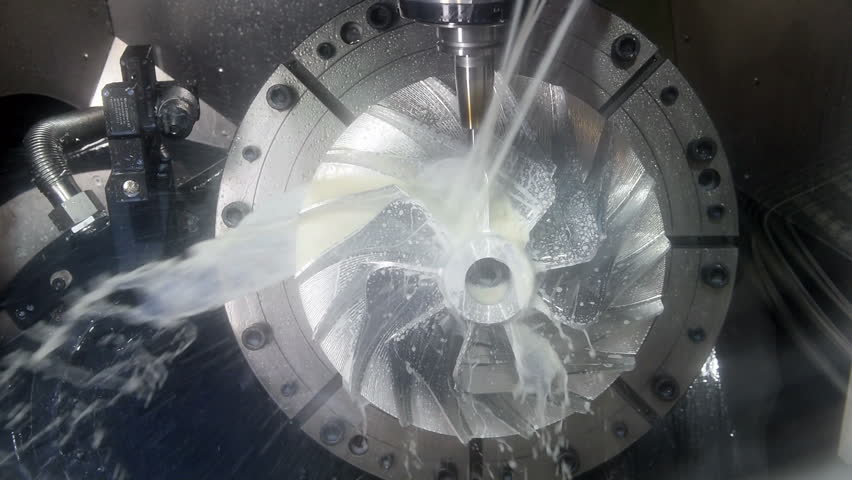

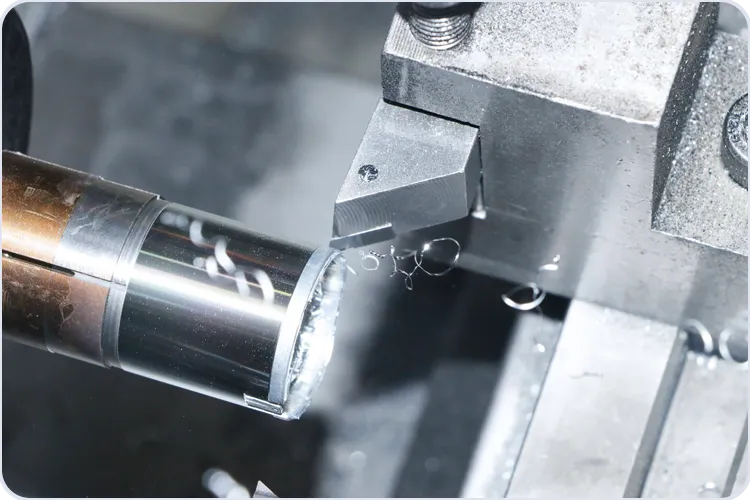

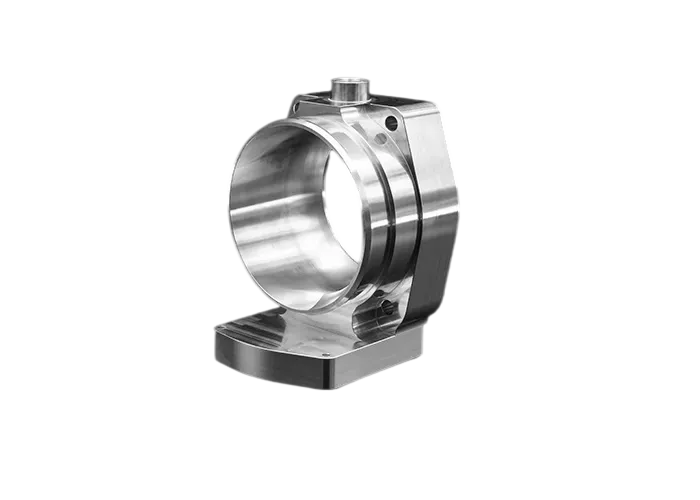

CNC Turning

Leveraging cutting-edge CNC lathes, we excel in manufacturing intricate cylindrical components, including those with tight concentricity and surface finish requirements. Our processes optimize speed and precision, ensuring exceptional repeatability and reliability for critical applications.

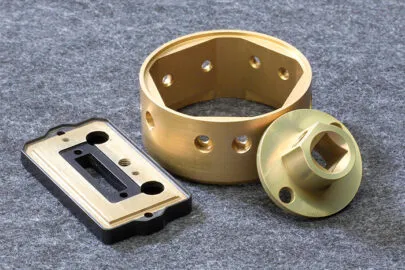

Material Expertise

Our machining capabilities extend to a diverse array of materials, including superalloys, high-strength titanium grades, aerospace aluminum alloys, stainless steels, and other high-performance metals. We provide expertise in handling material-specific challenges, such as thermal expansion, surface integrity, and machinability.

Advanced Lean Processes

We implement state-of-the-art lean manufacturing techniques, such as automated toolpath optimization, real-time process monitoring, and workflow automation, to minimize waste and reduce production cycles. This ensures cost-effective solutions while maintaining exceptional precision and adherence to project timelines.

AS9100 Certification

Adhering to AS9100 standards, we ensure comprehensive quality management systems, covering first article inspections, in-process validations, and final conformity checks. Our certification underscores our commitment to meeting the exacting quality and traceability demands of aerospace and defense sectors.

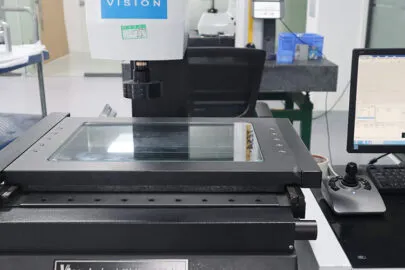

Outgoing Quality Control

Our outgoing quality control leverages advanced CAD monitoring tools and Zeiss CMM systems for precise part-to-model validation, ensuring compliance with design specifications. Zeiss metrology systems provide nanometer-level accuracy for 3D surface analysis, GD&T evaluations, and detailed inspection reporting.

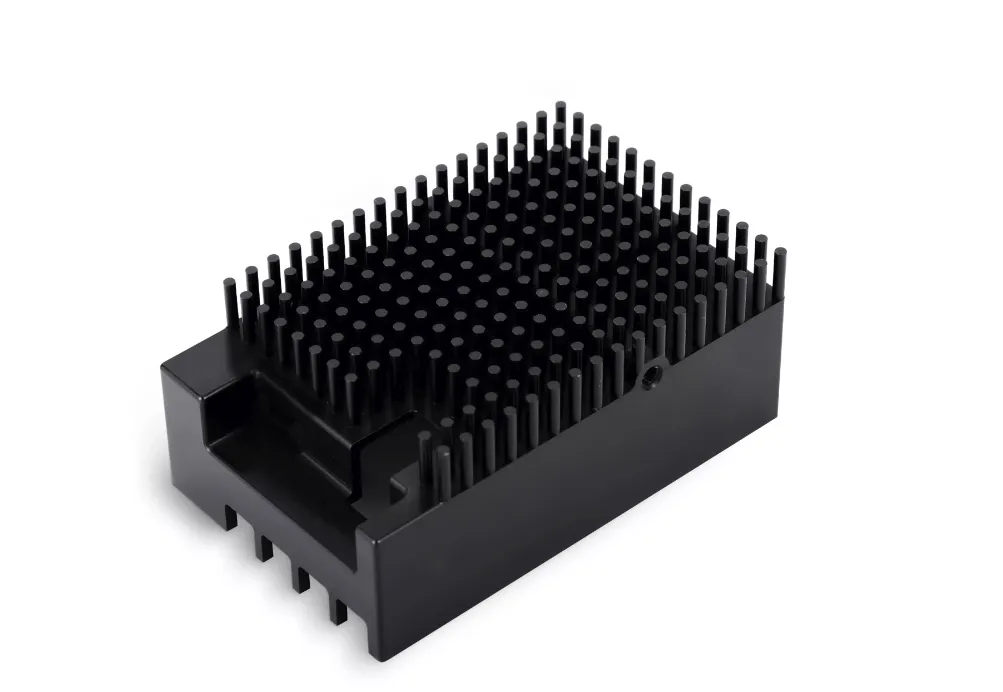

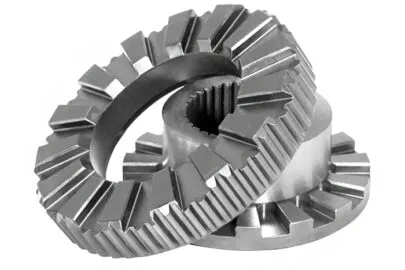

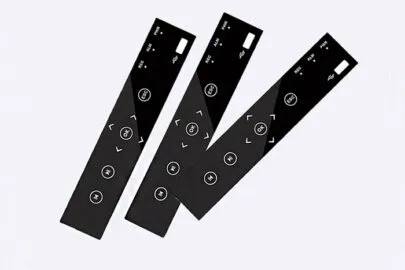

CNC Milling

3-axis, 4-axis and 5-axis milling, capable of milling flat surfaces, steps, grooves, spiral grooves, gears and other complex parts.

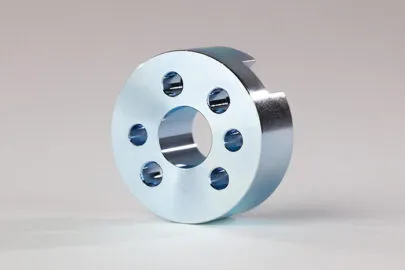

CNC Turning

CNC lathe, walking machine tool, lathe-milling compound, can process rotating curves, thread surfaces, end planes, and eccentric shafts, etc.

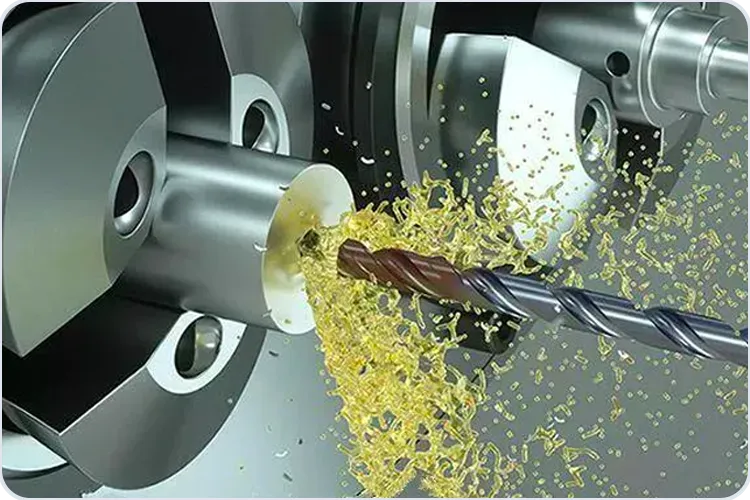

CNC Drilling

Vertical type, bench drill, radial drilling machine can be used for drilling in metals and alloys such as aluminum, steel, copper, and polymers.

More Techniques

Provide a variety of CNC machining such as wire cutting, EDM, grinding, boring, drilling, planing, etc.

Machining for Complex Parts

Machining raw materials

Aluminum

Lightweight, moderate strength, and good thermal conductivity.

Stainless Steel

Corrosion-resistant, high strength, and high temperature resistance.

Brass

Good conductivity, corrosion resistance, and easy to process.

Steel

High strength, suitable for multiple types, and can be passivated processing.

Titanium

High strength, lightweight, high temperature resistance, and good biocompatibility.

Polypropylene

Light weight, rigidity, chemical corrosion resistance.

Polymer Composite

High strength, light weight, and wear resistance.

PVC

Corrosion resistance, good electrical insulation, and high machinability.

PS

Light weight, moderate hardness, and good insulation

PETG

Impact resistance, transparency, and easy to process.

Carbon Fiber Composite

High strength, light weight, and corrosion resistance.

Glass Fiber Composite

Good strength and stiffness, and wear resistance.

Surface treatment

As Machined

The original state of a part after machining, without any additional surface treatment.

Anodizing

Type II anodise provides increased corrosion resistance and can be used as a base for paint and other finishes.

Alodine

Vertical type, bench drill, radial drilling machine can be used for drilling in metals and alloys such as aluminum, steel, copper, and polymers.

Bead Blasting

Depowdering of parts with bead blasting. The final parts are slightly grainy in the touch with a satin-like matte appearance.

Brushing

The brushing process helps to protect the surface of the workpiece, extend its lifespan, and improve its overall appearance.

Black Oxide

A process that forms an oxide layer on metal surfaces through chemical treatment to enhance corrosion resistance and reduce light reflection.

Chromate

A chemical treatment applied to metal surfaces to improve corrosion resistance and adhesion.

E-coating

A coating technology applied to metal surfaces through electrophoretic deposition to enhance corrosion resistance and provide a uniform coating.

Heat Treatment

Improve the hardness and strength of the metal through rapid cooling.

Laser Engraving

A technique that uses lasers to create precise markings or engravings on material surfaces without altering the material's structure.

Mirror Polishing

The process by applying a polishing compound to the part and achieve to a high gloss. Mirror polishing is much smoother and more durable than conventional polishing processes.

Painting

Use a spray gun to spray paint to provide uniform color and protection.

Plating

Plate a layer of chromium on the surface to improve corrosion resistance and appearance.

Powder Coating

Use static electricity to spray the powder on the surface to form a solid coating.

Passivate

A chemical treatment that forms a protective oxide layer on metal surfaces to enhance corrosion resistance and prevent further oxidation.

Silk Screen

A process that uses a mesh screen to transfer ink or paint onto a material's surface through a stencil, suitable for various materials and shapes.

Sand Blasting

Use high-pressure sand blasting to remove the surface oxide layer and rust.

Smooth Polishing

A process that uses mechanical or chemical methods to achieve a smooth, glossy, and even surface finish.

Burnish

type of machining can be used to improve the surface finish of parts and components, extend their.

CNC Machining Tolerances and Standards

If you have higher requirements for accuracy, you are welcome to emphasize it in the drawings or communicate with the engineer.

Standards

Maximum Part Size

Maximum Part Size

Standard Tolerances

Linear Dimension

Hole Diameters (Not Reamed)

Shaft Diameters

Edge Condition

Threads and Tapped Holes

Text

Lead Time

Part Size Restrictions

CNC Milling

1500×800×700(3 axis)

600×400×300

±0.01 mm

±0.01 mm

±0.01 mm

±0.01 mm

As machined deburring

≥1.0 mm teeth

≥0.2 mm teeth

5 business days

\

CNC Turning

\

\

\

±0.005 mm

±0.005 mm

±0.005 mm

\

\

\

\

φ284×406 mm

Various Inspection Facilities

ensuring meticulous inspection to deliver parts that meet precision and high reliability.

ZEISS CMM

Digital Altimeter

Automatic Image Measuring Instrument

X-RAY Analyzer

Surface Roughness Tester

Film Thickness Measuring Device

Calipers

OD Micrometer

ID Micrometer

Pin Gauge

HRC Tester

Thread Plugn Gauge

Request For Quote

We Also Provide You