At BAE LLC, our commitment to quality is built on a foundation of precision, reliability, and continuous improvement. We follow the mantra “Proper Planning Prevents Poor Performance”, ensuring that every project, from start to finish, is executed with meticulous attention to detail and the highest industry standards.

Certifications and Standards

AS9100 & ISO 9001

Guarantees that all machining processes adhere to the highest quality standards, making us a trusted partner for the aerospace and defense industries.

ITAR Registered Certification

Ensures secure handling and compliance with strict regulatory standards, making us a trusted partner for defense and aerospace projects requiring high levels of confidentiality and quality assurance.

IPC Classes 1, 2, and 3

For PCB manufacturing, we comply with IPC standards up to Class 3, ensuring top-tier performance for high-reliability applications.

Key CNC Machining Quality Measures

Our outgoing quality control process ensures that every part meets exact specifications before shipment, utilizing advanced equipment such as Hexagon CMMs, Keyence systems, Zeiss EQ equipment, and other industry-leading technologies.

First Article Inspection (FAI)

Each new part undergoes a

thorough first article inspection to verify that it meets all specified tolerances and dimensions before full-scale production begins.

In-Process Inspections

Continuous monitoring during machining ensures that every part adheres to tight tolerances and maintains consistent quality throughout production runs.

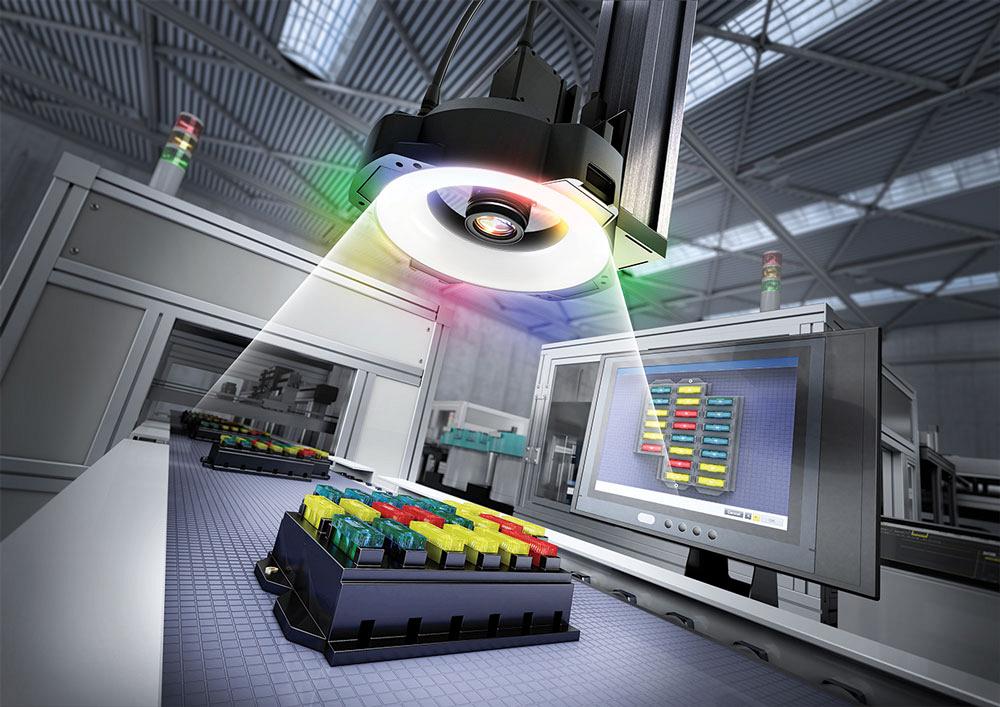

Keyence Systems

Used for advanced measurement and

inspection, these systems help ensure the integrity of critical

dimensions.

Dimensional Integrity

Our CNC machining centers are capable of achieving tolerances as tight as ±0.0001 inches, guaranteeing precision for even the most intricate designs.

Coordinate Measuring Machine (CMM):

We employ

industry-leading Hexagon CMMs, traditional CMMs, CMMs with CAD comparison, and Zeiss EQ equipment for high-precision

measurements, ensuring dimensional accuracy for even the most complex geometries.

Surface Finish Inspection

We provide both visual inspection and profilometry to verify that each part achieves the specified

surface finish.

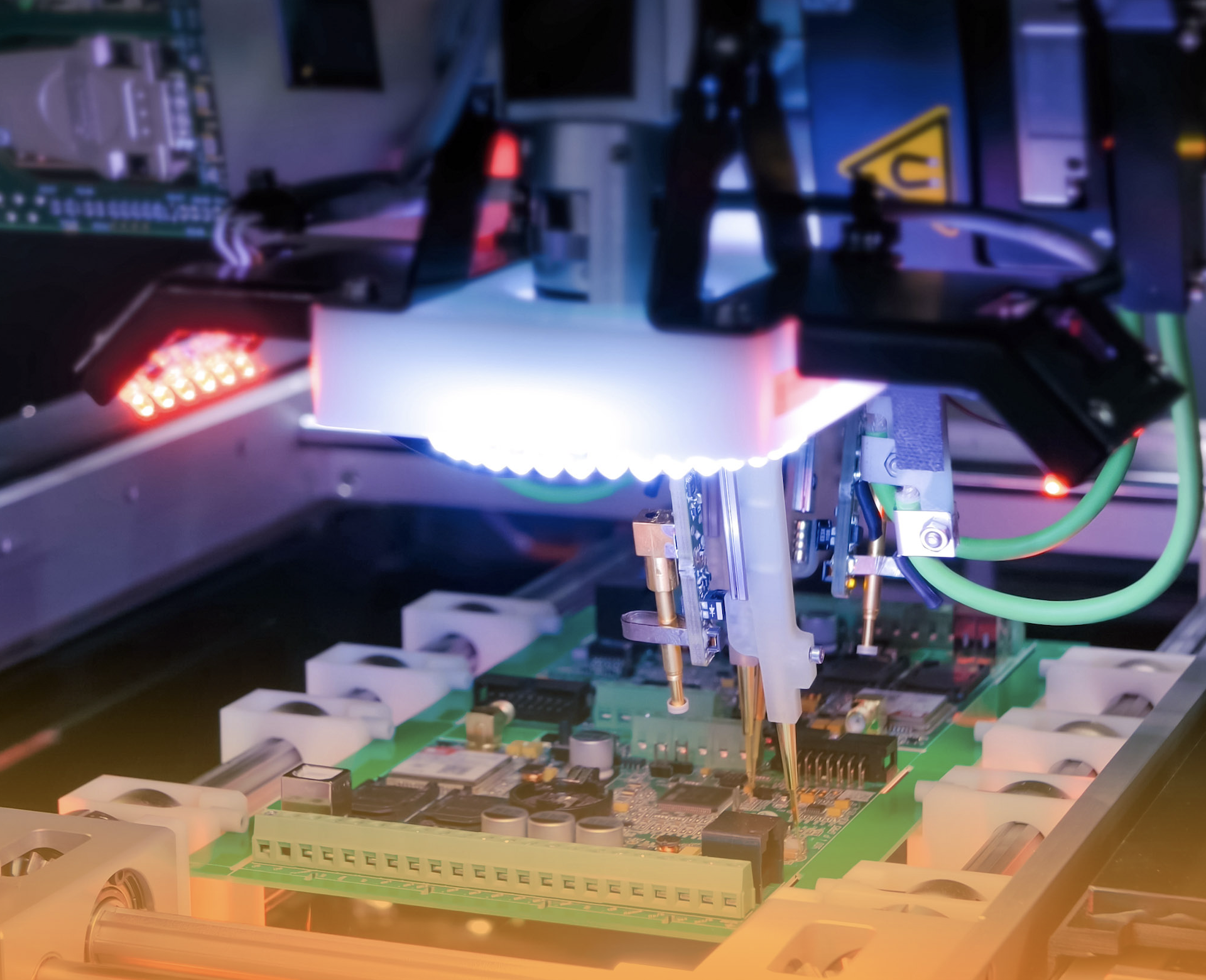

Key PCB Quality Measures

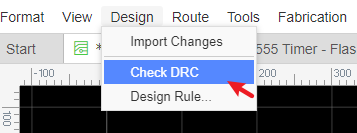

Design Rule Checks (DRC)

We conduct 300+ checks

throughout the design phase to ensure that your PCB design is

manufacturable and defect-free before production.

Impedance Testing

For high-frequency applications, we offer

precise impedance control with 5-10% tolerance, ensuring

consistent electrical performance.

First Article Inspection (FAI)

The first article of each production run is thoroughly inspected to confirm compliance with all design specifications before full-scale production begins.

Net List Testing (IPC-356)

Critical netlist verification ensures that the electrical connections align with design specifications.

Automated Optical Inspection (AOI)

Every board undergoes

AOI to detect defects or deviations, ensuring that every product

meets stringent quality requirements.

By adhering to IPC-600 guidelines and utilizing advanced manufacturing technology, BAE LLC guarantees exceptional PCB quality, delivering products on time and within budget.