Assembly Services Include

Component Sourcing and Supply Chain Management

BAE LLC ensures reliable component sourcing through a robust global supply chain, offering access to high-quality components from certified distributors. We handle critical part validations, ensuring traceability and compliance with industry standards.

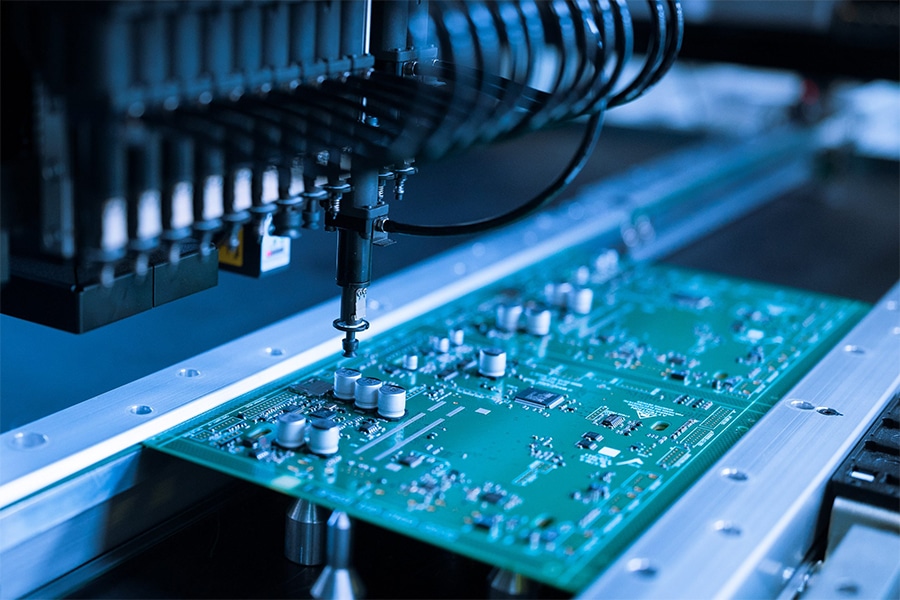

Surface Mount Technology (SMT)

Our advanced SMT capabilities include high-speed pick-and-place for components as small as 01005 and precise handling of BGAs, QFNs, and CSPs. With automated optical inspection (AOI), we ensure exact placement and soldering integrity for high-density assemblies.

Through-Hole Assembly

We specialize in precision through-hole soldering, including both automated and manual processes, for high-reliability applications. Our expertise covers mixed technology assemblies and components requiring advanced heat management.

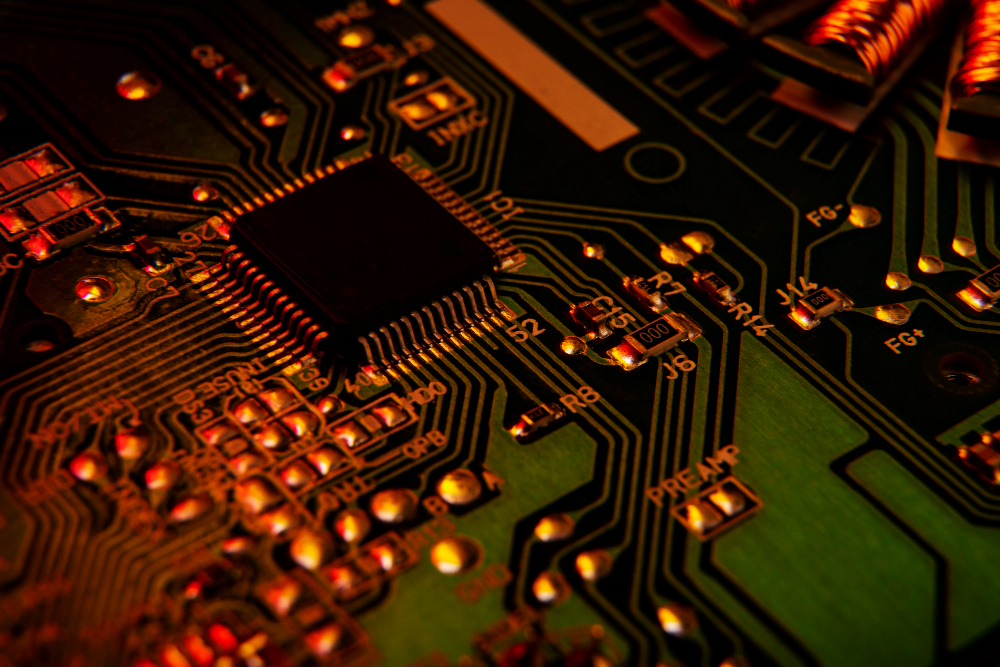

BGA and Micro-BGA Assembly

With x-ray inspection and reflow profiling capabilities, we ensure the precise assembly of BGAs and micro-BGAs, addressing challenges like void reduction, alignment, and solder joint integrity for advanced PCBA designs.

Functional Testing

Our assembly process integrates comprehensive testing solutions, including in-circuit testing (ICT), boundary scan, and functional tests. This ensures each board meets strict performance specifications and operational reliability before shipment.

Conformal Coating and Environmental Protection

We provide conformal coating services for PCBs requiring protection from moisture, dust, and chemical exposure. Our capabilities include spray, dip, and selective coating processes to meet specific environmental standards.

Integration