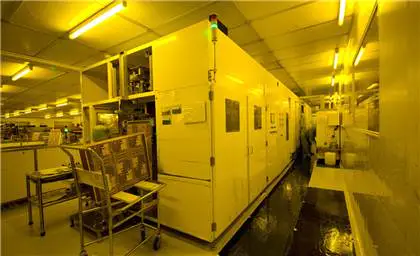

PCB Manufacturing Equipment

Strength in Precision PCB Manufacturing

At BAE LLC, our commitment to high-end PCB production is reflected in our advanced

equipment. The use of cutting-edge PCB manufacturing tools allows us to increase production

efficiency, enhance accuracy, reduce costs, and minimize errors. Our equipment enables us to

produce high-quality, complex PCBs, including HDI PCBs, RF PCBs, hybrid RF PCBs,

backplane PCBs, embedded PCBs, and other specialized technologies.

PCB Manufacturing Equipment

1. LDI (Laser Direct Imaging) Exposure Machine

The LDI exposure machine offers several advantages over traditional CCD semi-automatic

exposure machines:

- Precision: Direct imaging without film production reduces errors and ensures accurate circuit exposure.

- Efficiency: Shortens sample delivery time and reduces alignment errors, crucial for high-precision circuits.

- High-Resolution Circuits: Although slightly slower than CCD, the LDI is indispensable for producing high-precision, complex circuits.

2. Electrostatic Spraying System

Our electrostatic spraying technology is optimized for high-volume PCB manufacturing:

- Ink Coating: Applies solder resist ink for a durable coating, suitable for both prototype

and batch boards. - Advantages: Saves on skilled labor, suited for high production but requires maintenance

due to high ink consumption.

3. Full Auto Exposure and Automatic Exposure Machines

To meet the high precision and multi-layer requirements, we utilize both full and automatic

exposure machines:

- CCD Visual Alignment: Ensures fast, accurate alignment with consistent results.

- Precision: Maintains alignment accuracy up to ±10 μm, essential for fine circuits and

small apertures.

4. Quadratic Element Measuring System

The quadratic element measuring system provides detailed measurements to verify the precision of complex PCB elements, ensuring high standards in quality control.

5. Vacuum Laminator

A key asset in multi-layer PCB manufacturing, our vacuum laminator ensures consistent,

high-quality lamination:

- High-Layer PCBs: Enables production of multi-layer and ultra-multi-layer circuit boards

with reliable results. - Capability: Used primarily for boards with four or more layers, essential for high-strength

multi-layer boards.

6. Laminating Machine

Our laminating machine enhances multi-layer PCB production by securely bonding layers

together. This process is crucial for the strength and stability of multi-layer boards.

7. Vertical Continuous Plating (VCP) and Vertical Conveyor Plating

Our VCP equipment offers stable, high-efficiency copper plating capabilities with deep plating

ability:

- Efficiency: Allows continuous movement through the plating process, with uniform

production conditions. - Performance: Achieves superior copper plating uniformity, reducing costs and

enhancing quality.

8. Chemical Cleaning System

Chemical cleaning is an essential step to remove contaminants and prepare surfaces for further

processing, ensuring optimal adhesion and finishing quality.

9. Laser Drilling and Hitachi Drilling Machines

Our laser and mechanical drilling systems enable precise hole production:

- CO2 Laser: Ideal for industrial microvias larger than 100 μm with rapid drilling times.

- UV Laser: Suitable for smaller holes under 100 μm, essential for high-density circuit boards.

- Hitachi Drilling Machines: Adds versatility with precise mechanical drilling for different hole sizes and types.

10. Character Printer

Our high-precision character printer enables efficient, high-quality character spray printing on PCBs:

- Advantages: Replaces traditional silkscreen printing, offering stability and accuracy.

- Benefits: Shortens production cycles, provides high-quality printing, and reduces labor costs.

11. Gold Finger Beveling Machine

Used for creating gold fingers on PCBs, this machine ensures precise and consistent beveling,

crucial for connectors in high-performance applications.

12. Palletizing Machine

The palletizing machine helps automate material handling, enhancing efficiency and reducing

manual labor. It’s essential for high-volume production environments to streamline operations.

13. Appearance Visual Inspection

For quality assurance, we employ an advanced appearance inspection machine that detects

surface and structural defects:

- Precision Inspection: Identifies flaws such as exposed copper, scratches, ink issues, and solder mask inconsistencies.

- Benefits: Ensures every PCB meets stringent quality standards, essential for high-volume and high-quality PCB production.