Advanced Printed Circuit Board Manufacturing

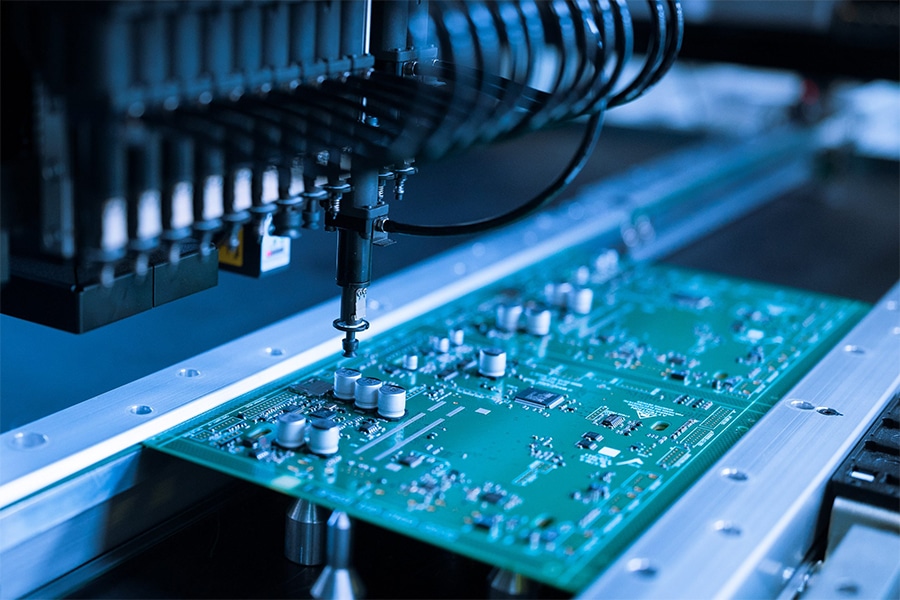

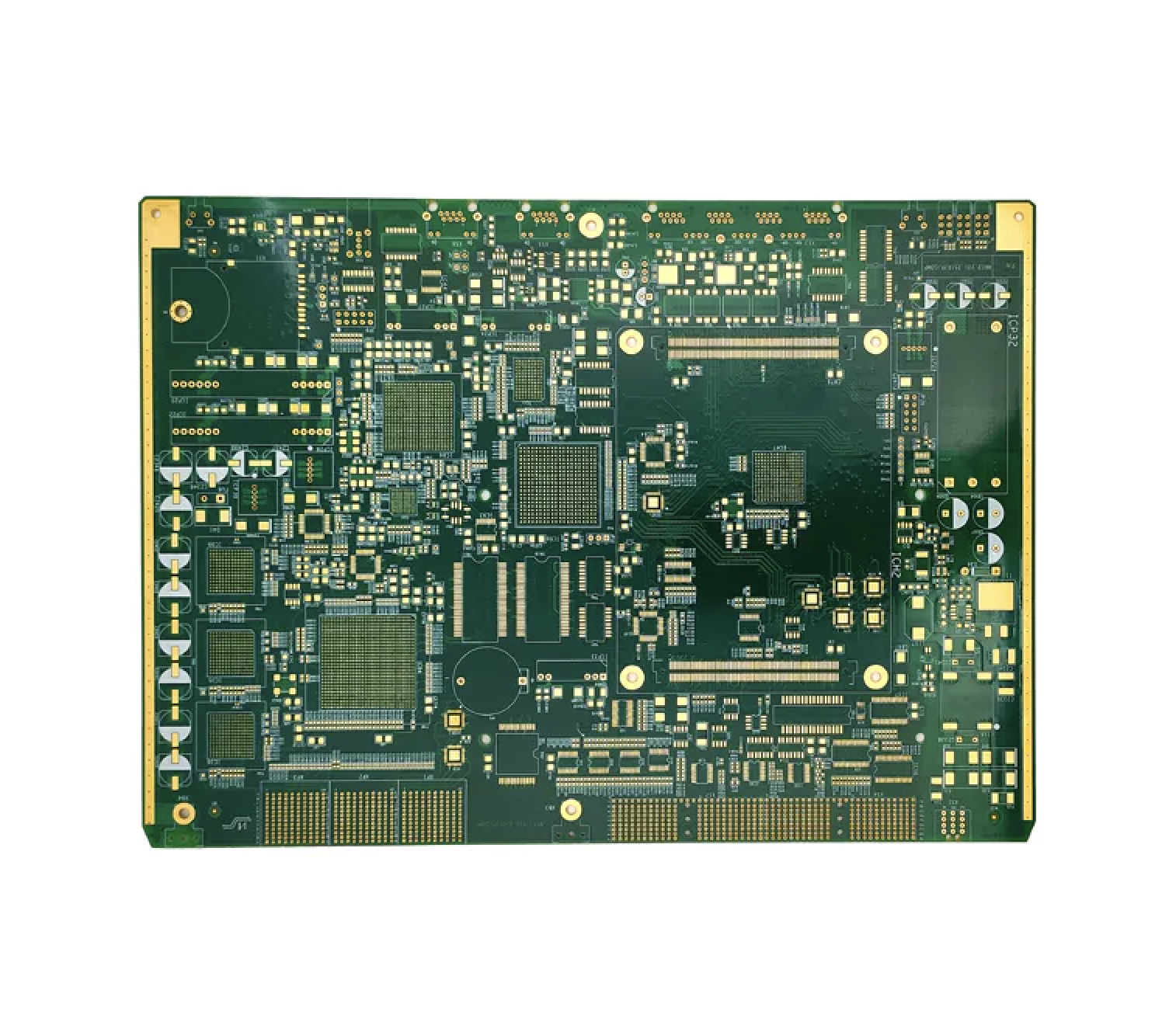

Through BAE’s ProtoPCB subsidiary, which has been a trusted name in the industry since 1972, we specialize in both PCB prototyping and manufacturing, offering fast, reliable, and cost-effective solutions for complex, high-performance applications. Whether you’re in the aerospace, robotics, medical, or automotive industry, our expertise ensures that your projects, from early-stage prototypes to full-scale production runs, meet the highest standards of quality and performance

PCB Fabrication Capabilities

Layer and Design Versatility

BAE LLC can manufacture PCBs with up to 64 layers, supporting Rigid, Flex, and Rigid-Flex designs. Our capabilities allow for board thicknesses up to 10 mm, minimum line widths and spaces of 1.5/1.5 mil, and laser-drilled holes as small as 3 mil.

Advanced HDI and Via Technologies

We offer cutting-edge High-Density Interconnect (HDI) capabilities, including 4+N+4 stack-ups, copper-filled vias, and Plated Over Filled Vias (POFV) for enhanced electrical performance. These features support high-speed, high-frequency applications with precise impedance control.

Extensive Material Options

With one of the broadest material portfolios in the industry, we provide a range of laminates, including PTFE, high-speed/low-loss, high-temperature, and low CTE materials. This enables us to handle RF/digital hybrid constructions and ensure material availability for time-sensitive projects.

Comprehensive Surface Finishes

Our surface finish options include ENIPIG, ENIG, HASL, Sn/Pb reflow, immersion silver, immersion tin, and others. We offer a finish for every application need, ensuring compatibility with both high-reliability and high-frequency designs.

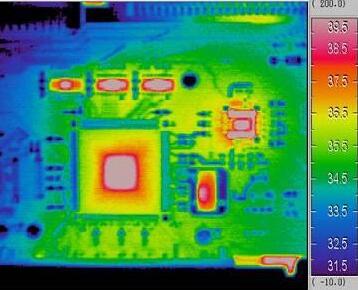

Heavy and Thick Copper Capabilities

We excel in thick copper PCBs, with copper thicknesses up to 10 oz, ideal for high-power, high-current applications requiring efficient heat dissipation. Our expertise covers multi-layer plating, solder mask applications, and precise copper deposition to meet stringent customer specifications.

Precision Manufacturing and Quality Control

BAE LLC employs advanced manufacturing processes and quality control measures, ensuring high precision and compliance with industry standards. Our team manages complex requirements, including controlled impedance and multi-layer designs, to deliver reliable, high-quality PCBs.

Unmatched Speed, Reliability, and Value

BAE LLC provides industry-leading speed and reliability with 24/48/72-hour turn times, the quickest average cycle, high on-time delivery rates for high-layer counts, and a 98.6% success rate on advanced boards—all while offering a broad range of standard tech options at no extra premium.

Broadest Standard Technology Spectrum for PCBs

| Item | Standard | Advanced | Item | Standard | Advanced | ||

| Max Layer Count | Rigid | 64 | 68 | Copper Weight | 1/5oz – 10oz | 1/7oz – 12oz | |

| Flex | 6 | 8 | Hole(min) | Mechanical | 200um | 150um | |

| Rigid-Flex | 20 | 24 | Laser | 100um | 100um | ||

| Thickness | Rigid | 0.2mm – 10mm | 0.1mm – 14mm | Vias’ Pad | Mechanical | 350um | 300um |

| Flex | 0.08mm – 0.8mm | 0.06mm – 1.0mm | Laser | 250um | 200um | ||

| Size | Width | 10.0mm – 800.0mm | 3.0mm – 900.0mm(Multi800) | Hole Aspect Ratio | 1:16 | 1:18 | |

| Length | 10.0mm – 1500.0mm | 3.0mm – 2100.0mm(Multi1320) | Min Deletric Thickness | Inner Core | 0.025mm | 0.025mm | |

| Tracks | Width | 70um | 50um | Prepreg | 0.05mm | 0.05mm | |

| Gap | 70um | 50um | HDI | 5 + N + 5 | 9 + N + 9 | ||

| Via Filling(with) | Soldermask/Resin/plating/copper & silver paste | Solder Mask Bridge | 75um | 60um | |||

| Embedded Passive | Capacitor | 3M C-Ply, Dupont HK04J,Sammina (BC-2000), Mitsu Faradflex,OKA-Mitsui,Faradflex BC12M, BC24M Dielectric thickness:12um,14um,25um Capacitance/area:0.8nF/in2 – 10nF/in2 No license needed/Customization | Materials | Standard FR4,lead free compatible High speed, low loss Halogen free High Frequency Advanced microwave materials from Rogers/Arlon/Taconic,etc. Special application material such as copper invar copper,customization etc. | |||

| Resistor | Resistance(ohms/sq):25,50,100,200;Ohmega-Ply,Asahi Tu-50/1000-08, Ticer, Nichrome | ||||||

| Materials | Burried Copper/Ceramic/Coin/Steel/other metal/Components | Surface Treatment | Soft gold Hard gold Flash Gold OSP ENIG HAL LF HAL Immersion Tin Immersion Silver ENEPIG | ||||

Tolerance(+/-) |

Hole |

0.075mm |

0.025mm |

||||

Slot | 0.1mm | 0.05mm | |||||

Tracks | 15% | 10% | |||||

Outline | 0.1mm | 0.08mm | |||||

Impedance | 8% | 5% | |||||

Dielectric | 15um | 10um | |||||

Depth Control | 150um | 100um | |||||